Additive Manufacturing: 3D Printing

3D Printing

Unlike subtractive manufacturing, 3D printing allows you to produce incredibly complex products. Better yet, it can produce these products quickly, with minimal lead times, which makes additive manufacturing the ideal method for developing prototypes or low volume / custom products. With many simulation parts being static, or non-functioning, STS can produce these static parts at a fraction of the cost of real parts. In addition, 3D printing efficiently uses nearly 100% of the raw material, leading to minimal, if not zero waste.

There are many different types of additive manufacturing processes, each with its own advantages and disadvantages. The most common processes used at STS are:

Fused deposition modeling (FDM): This is the most common type of 3D printing process. It uses a heated nozzle to melt thermoplastic filament, which is then deposited layer by layer to create the object.

Stereolithography (SLA): This process uses a laser to cure a liquid resin layer by layer.

3D Printed Training Mockups

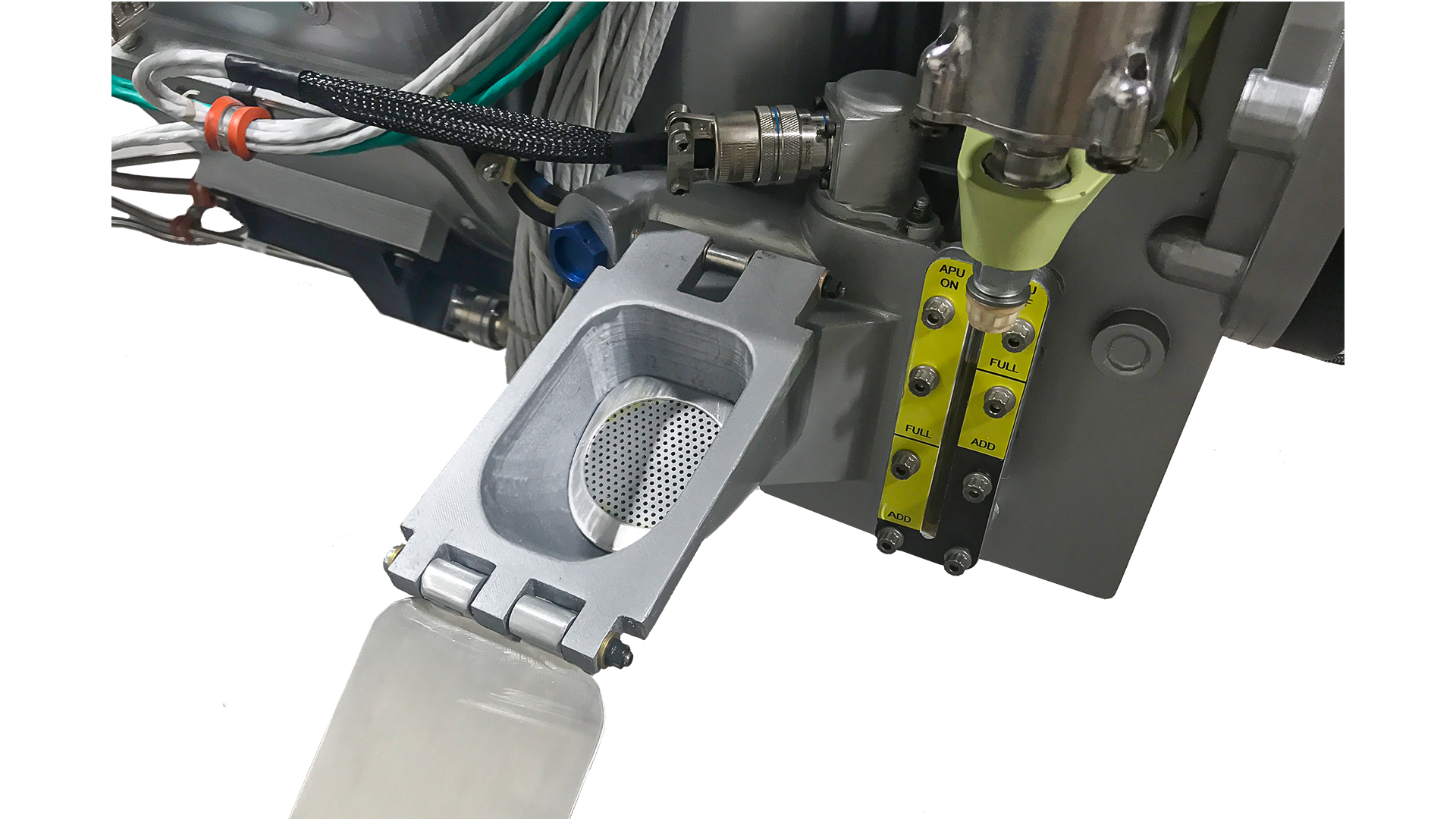

Derived from 3D scans of the aircraft APU - this 3D printed APU mockup is an exact replica of it’s OEM counterpart. Constructed entirely of FDM 3D, manufactured, aircraft, and COTS parts, real-world maintenance training is made possible without the need to procure an OEM aircraft assembly.

The APU assembly is weighted and balanced to OEM specifications including utilization of the aircraft mounting system. This allows for proper installation into the aircraft and training support equipment. R&I task parts are also designed and manufactured to OEM specifications. The required details of each task part is present including: fittings, connectors, packing (O-rings), wiring connectors, and hardware. Replacement parts and spares are easily obtainable decreasing lead times and costs.

3D Printed Aircraft APU

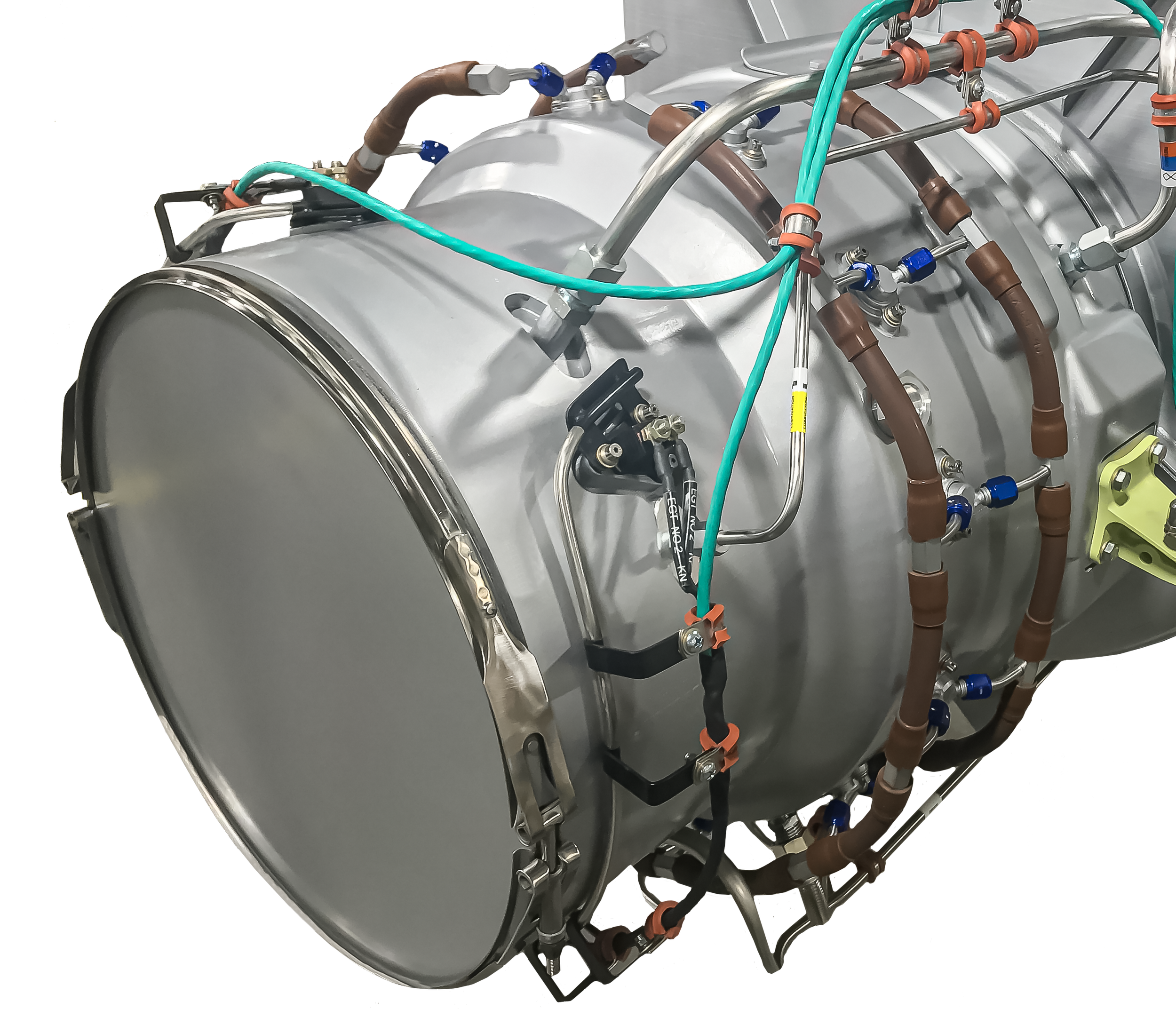

Aircraft Radar 3D Print Mockup

P-8A Poseidon Radar Mockup

The Aircraft Radar Mockup is comprised of a 3D printed body with a mixture of manufactured, COTS, and aircraft parts. Used for R&I task training, this high-fidelity mockup is an exact replica of the Aircraft assembly utilizing aircraft hardware, cable connectors, and interfaces. Spares and assembly parts are easily re-produced significantly reducing lead-times and customer costs.